Welcome to our Spiralizing World

High Carbon Performance, Low Carbon Footprint

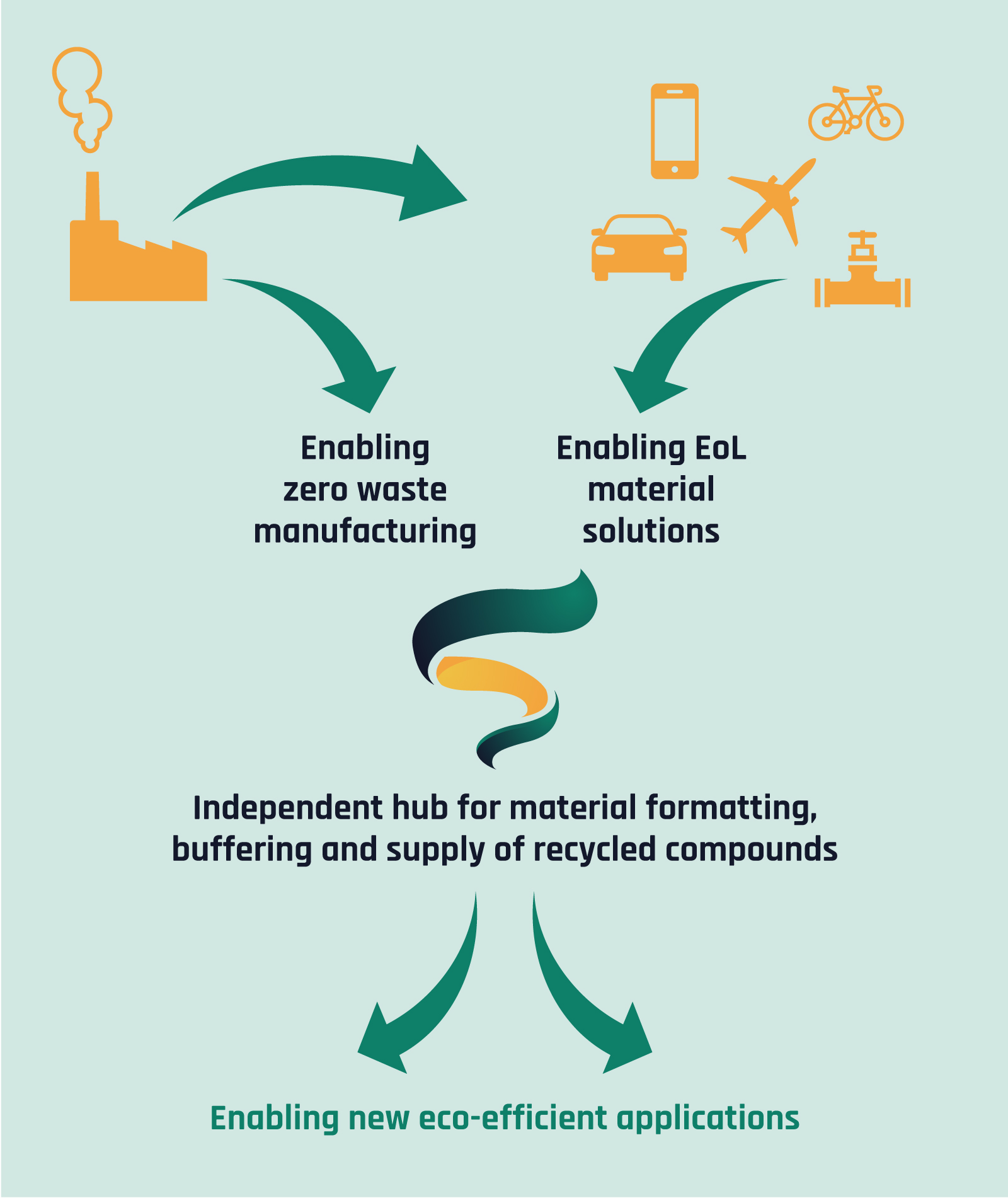

SPIRAL Recycled Thermoplastic Composites offers a sustainable solution to realize circularity for carbon fiber thermoplastic composite production waste and end-of-life. SPIRAL collects, processes and markets these high end materials in generic recycled formats. The new lease on life for these materials in high-end applications significantly reduces the overall CO2 footprint. SPIRAL thereby closes the loop and unleashes the full potential of carbon fiber thermoplastic composites as circular and sustainable engineering materials.

Shaping Circularity

Carbon Fiber Reinforced Thermoplastic Composites are intrinsically sustainable materials; they offer a versatility in design enable extreme lightweight solutions for a range of applications. SpiralRTC adds a feature to these sustainable materials. It enables the implementation of circular TPC material use

Mission

To provide an independent industrial resource for sustainable recycling of carbon fiber thermoplastic composite production waste and end-of-life components to new material formats based on recycled fiber reinforced thermoplastics.

Why Spiral?

Together, we can make an impact. Embedding circular use of thermoplastic composites ensures both an ecologic as well as an economic impact.

Circular use of these materials results in a significant reduction of the carbon footprint and is required to meet the upcoming circularity goals. In addition, re-use of these strategic materials reduces the depletion of our natural resources.

These materials typically possess an inherent value. Burning is a waste. SpiralRTC regains the inherent value of the waste streams to high end products with a low footprint and competitive pricing.

What we do

Collect Thermoplastic Composite

At SPIRAL RTC, we lead the way in transforming thermoplastic composite waste into high-performance, sustainable materials. Our innovative recycling processes handle both post-industrial recyclate (processing waste) and post-consumer recyclate, including end-of-life solutions for products. By focusing on zero-waste recycling, we help industries efficiently implement circular solutions, ensuring no material is wasted.

Processing to new compounds

Our recycling process achieves nearly 100% material yield, recycling both the thermoplastic matrix and the fibers. Built on low-energy and highly efficient methods, our technology minimizes environmental impact, with less than 2 kg of CO2 emissions per kg of recycled material — making our solution 10 times more efficient than producing virgin materials. Additionally, our process has a lower carbon footprint than incineration, retaining maximum material value with minimal energy use.

Supply of recycled compounds

Spiral RTC provides high-end recycled compounds with excellent mechanical performance, chemical and corrosion resistance, and fire retardant properties. These thermoplastic composites are of the same quality as new materials and are suitable for a wide range of manufacturing technologies, including injection molding, additive manufacturing, and other hybrid processes. Our recycled compounds are ideal for industrial applications, consumer products, mobility solutions, and energy-related industries. We not only supply recycled materials but also help our clients close the loop by offering tailored recycling solutions for their own products.